Working with 3D Printed Resin Miniatures

Bestiarum’s resin miniatures are made using the latest high-resolution 3D printing technology. This guide will help you understand how our print-to-order resin miniatures are made, what to expect when handling them, and how to get the best results in your hobby - whether you’re a painter, collector, or wargamer.

This guide is written for our Print-to-Order customers, but much of the advice applies to anyone working with resin miniatures.

Made to Order Catalog

We do not keep physical stock. Every model is printed on demand when your order is placed. This process typically takes 2–4 weeks, depending on print queues and the size of your order.

All miniatures are printed using high-resolution resin printers at a layer height of 0.025mm, capturing extreme detail for a professional finish.

Durable, High-Quality Resin

Our custom resin blend is designed to balance durability with fine detail. It’s more robust than traditional brittle resins but will still snap under excessive pressure, unlike plastic which may bend instead.

If you’re used to plastic miniatures (like polystyrene or PVC), resin feels a bit different. It’s closer in nature to cast resin used by traditional miniature makers. Whatever your experience, we’re confident you will find this new material easy to work with.

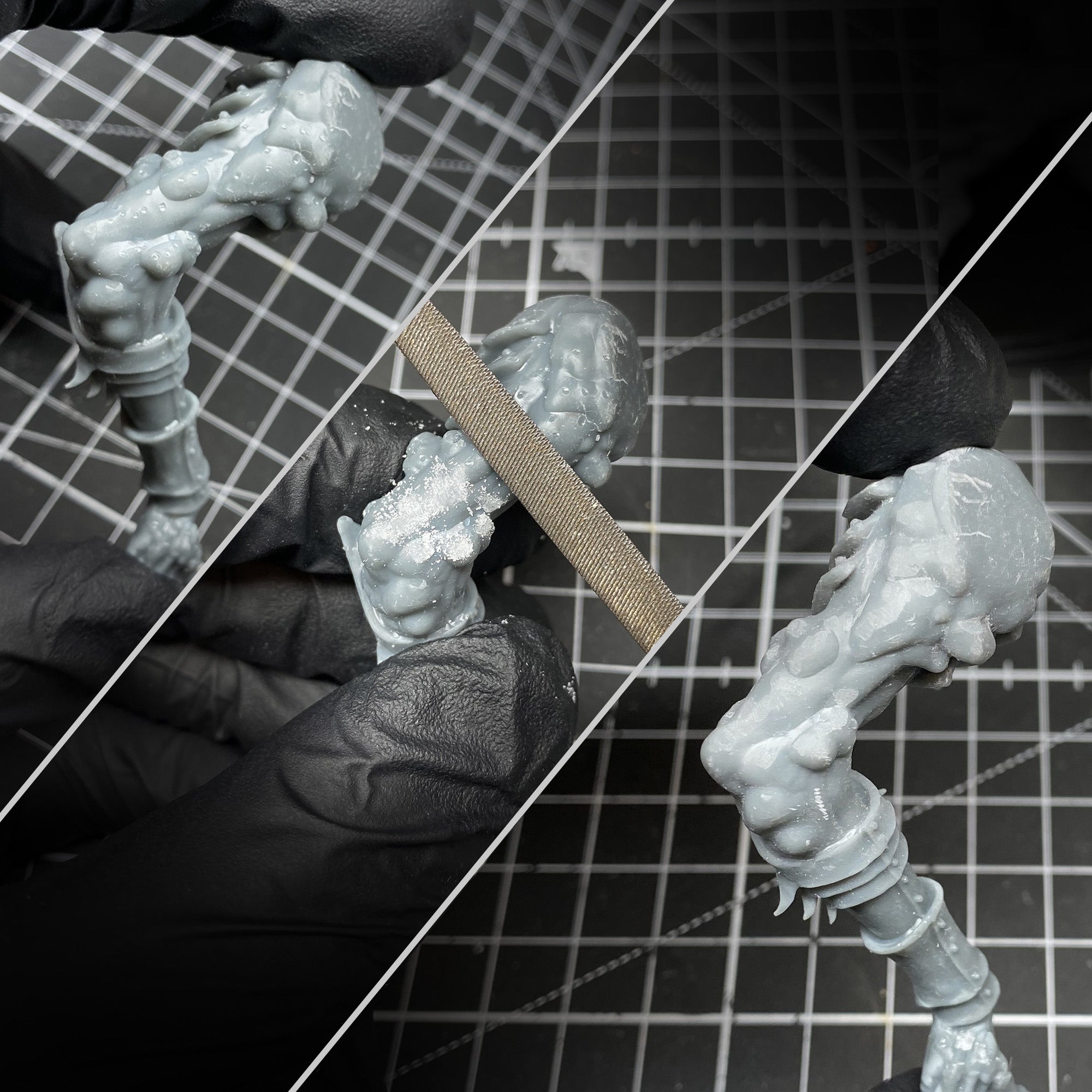

Cleaning & Finishing

Every model is thoroughly washed and UV-cured before shipment by our expert team.

Some light cleanup may still be required to remove:

- Small support marks

- Minor surface imperfections

These are common, and a natural byproduct of the printing process, in most cases, supports are placed on less visible parts of the model, so any detail loss is mitigated.

We recommend the use of surface fillers such as Liquid Greenstuff or Mr. Surfacer, or gentle sanding/filing for a perfect finish.

Safety Tip: Resin dust is hazardous if inhaled. Always wear a mask when sanding and work in a well-ventilated area. Be sure to clean up your workspace afterward.

Layer Lines

All 3D prints are built layer by layer, which means faint layer lines may be visible, especially on large, smooth surfaces like flowing robes or cloaks.

We employ a variety of tricks to minimise and avoid layer lines, which eliminates the issue on most miniatures.

In the situations where it cannot be avoided entirely, layer lines can be:

- Disguised with primer (most disappear after a single coat)

- Smoothed using liquid fillers

- Covered with textured paint or effects

Assembly

Miniatures are supplied unassembled in multiple parts.

We recommend:

- Superglue (cyanoacrylate) for bonding, especially Gel-Type Glues.

- Dry-fitting parts before gluing for best alignment

- Optional use of a superglue activator for fast setting.

Important Safety Information

- These miniatures are not toys and are not intended for children

- They contain small parts that may pose a choking hazard

- Resin dust can be toxic — always wear a mask and clean up thoroughly after any sanding or modification

- Resin, even cured, should never be ingested to the body.

Questions or Concerns?

We want you to be completely satisfied with your miniature.

If you have any questions about handling, assembling, or painting your models, or if you encounter issues with a product you’ve received, then please don’t hesitate to reach out.

Whether you're unsure about cleanup, missing a part, or something just doesn’t look right, we’re here to help.

We’re a small team, but we take pride in our craft and in supporting our community. Your feedback helps us improve, and we’ll always do our best to make things right.